“Digital twin” is one of the buzzwords surrounding digitalization in the IoT and Industrial IoT industries. This technology offers a wide range of application possibilities in Industry 4.0 and also takes digitalization a big step forward.

What is a digital twin?

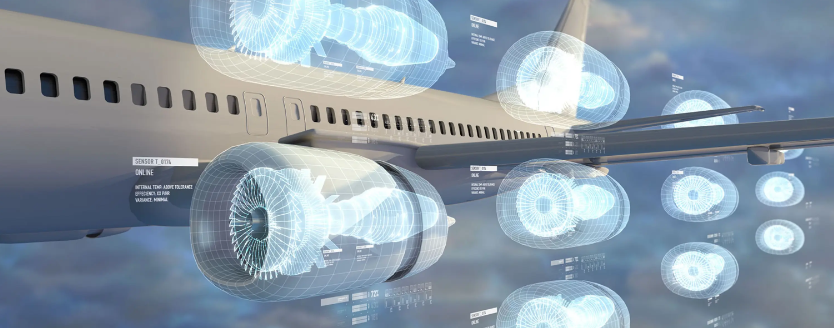

A digital twin is a digital virtual representation of a physical object or process. These digital representations are provided by real-world data taken from sensors in the physical world, which are processed using artificial intelligence technology. That is, these data allow a virtual representation of real processes. Through digital twins, behaviors can be simulated, objects or processes can be predicted, etc.

In industrial settings, we often see digital twins of products or processes.

The principle of digital twin

The objects under study, such as wind turbines, are equipped with various sensors related to These sensors generate data about different aspects of the physical object’s performance, such as energy output, temperature, weather conditions, etc. The processing system receives this information and actively applies it to the digital twin.

Once relevant data is obtained, digital models can be used to perform various simulations, analyze performance issues, and create potential enhancements. The ultimate goal is to gain valuable knowledge that can be used to improve the original physical entity.

Types of digital twins

Digital twin technology can be divided into four different types, each with its own unique characteristics and advantages. These are component, asset, system and process twins. Let’s look at each in more detail:

component twin

Component twins are digital models of individual components or parts, such as motors, sensors, switches and valves. They provide detailed information about component performance and behavior in real time and over time. This helps monitor the health and performance of these components and make necessary changes if needed.

Asset twin

Asset twins are digital models of physical assets such as buildings, machines and vehicles. They provide real-time information about asset operating status, performance data and environmental conditions. This helps organizations reduce downtime and increase operational efficiency.

system twin

A system twin is a digital model of an entire system or process. They enable organizations to monitor and analyze the performance of their systems and identify areas for improvement. System twins enable organizations to optimize their processes and improve the way they operate.

process twin

A process twin is a digital model of an entire business process or customer journey. They provide detailed information about how customers interact with an organization’s products and services in real time. This helps organizations identify areas where customer experience can be improved.

Digital twin platform

The digital twin platform is a technical system that integrates physical models, sensor data, operation history and other information. It simulates, monitors and optimizes the entire life of physical equipment by constructing a digital copy of the physical equipment or system in the virtual space that is exactly the same as the physical equipment or system. cyclic process. Building a digital twin platform requires multi-departmental teamwork, and the workload is large and time-consuming. If you use the Sovit3D low-code visualization platform for development, the development efficiency will be greatly improved. Sovit3D came into being in the environment of information technologies such as 5G, big data, and the Internet of Things.

The Sovit3D platform adopts a B/S architecture and is based on WebGL drawing technology standards. It provides 3D visualization industry components based on Web browsers, supports the latest technologies such as HTML5/SVG, and can be easily browsed and debugged on the browser. Create large-screen visualization applications for developers that meet user habits, including 2D chart analysis, 3D architectural scenes, 3D industrial equipment models and other related content. It can be easily drag and drop to control real-time data and animation display, historical playback, alarm, Command issuing and other functions.

The Sovit3D platform provides massive 3D models, and you can also upload customized models online; zero-code visual online editing, fully automated scene file generation; access to multiple data sources, easy seamless data docking with third-party platforms, and visual settings for real-time animation effects. It can be introduced into third-party systems with simple settings… It has many features, and IoT visualization developers can log in to the platform to try it out.

The future of digital twins

Existing operating models are undergoing fundamental changes. Digital reinvention is taking place in asset-intensive industries that are changing operating models in disruptive ways, requiring integrated physical and digital views of assets, equipment, facilities and processes. Digital twins are an important part of this adjustment.

The future of digital twins is almost limitless as more and more cognitive capabilities continue to be put into their use. As a result, digital twins are constantly learning new skills and capabilities, meaning they can continue to generate the insights needed to make products better and processes more efficient.

As adoption continues to increase, digital twins will find more applications in everything from urban planning to product development and factory simulation.